A5-203, Gaoli Auto Expo City, Huishan, Jiangsu, China.

A5-203, Gaoli Auto Expo City, Huishan, Jiangsu, China. Annie +86-189 61880758 Tina +86-15370220458

Long ago, cloth was made by hand. They really put in an effort to sew each piece of fabric together to make beautiful clothes. It may have been time-consuming and labor-intensive but it was the only way to produce textiles at the time. Then something amazing happened — the GOODFORE automatic weaving machine was invented! So this new machine changed weaving forever. It can accelerate & simplify the whole process for all channels involved. Now, let's find out more about this awesome invention and how it helps make clothes for us today!

A man called Edmund Cartwright invented the automatic loom machine in the 1700s. His goal was to simplify how workers made cloth. Prior to this machine, weaving was done by hand using a tool called a shuttle. The shuttle had to move back and forth through the threads of the fabric. This process was laborious, and each loom could produce only small amounts of fabric each day. As a result, the number of clothes people could make was limited.

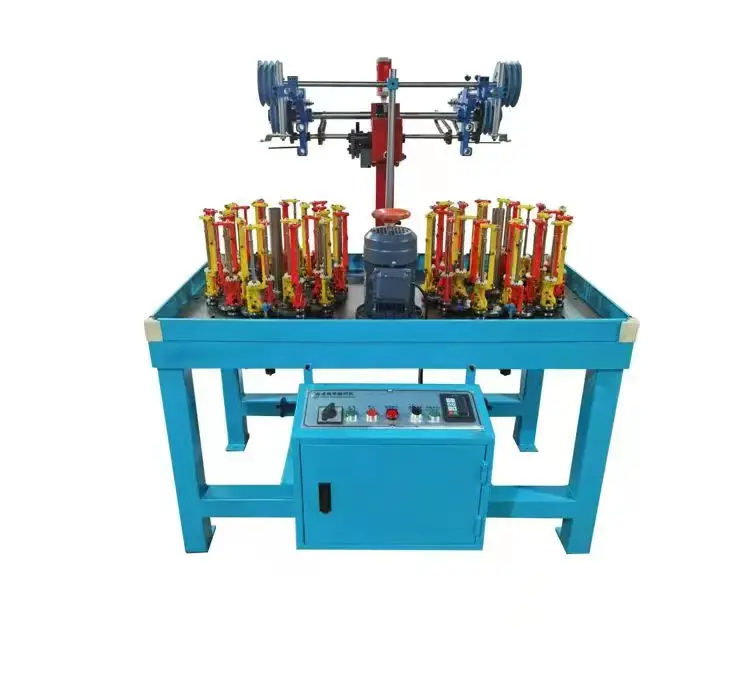

This was, however, totally revolutionized by the invention of the automatic loom machine! It relied on a special system of hooks and needles to automatically move the threads. This sped the process and made it easier to mesh. Now workers were able to make much more in a shorter time frame rather than working all day for a small piece of fabric. This GOODFORE Needle Loom Machine led to faster and cheaper cloth production. That was a huge deal for factories and for people who needed clothes.

Now, textile factories across the globe employ automatic loom machines. I can’t imagine producing cloth without them! Photos of factories were convenient places to make fabric at high speed. Some modern looms even incorporate computers to assist the weaving process, resulting in an even better and more precise craft. This means the machines can produce fabric faster than ever and of improved quality.

They achieve very high efficiency and productivity in contrast to automatic loom machines. They can work 24 hours per day, 7 days per week without stopping or sleeping. The output requisition that factories can produce textiles like never before, which is significant to quench a wear demand of cheap clothing. There are plenty of reasons why people need clothes, and these GOODFORE needle loom machine ensure that everyone has enough of what they need.

Textiles manufacture is a vital element of the world economy. It offers jobs and clothing for millions of people around the world. Automatic looms have been a part of turning textile making as fast, simple, and low-cost as possible. As companies, brands and organizations continue to discuss the importance of textiles and the future of textile manufacturing as new technology is developed all the time, the future of textile manufacturing has never looked so exciting!

At GOODFORE, we believe in providing our customers the best quality fabrics at good prices. That is why our products are made using the latest automatic GOODFORE Textile Machinery technology. We will be integrating those new ways into the future of how to make textiles and are excited to be seeing another great time around textile making! We must continue iterating and seeking new approaches on improving our products even further.

Copyright © Goodfore Tex Machinery Co., Ltd. All Rights Reserved - Privacy Policy - Blog