A5-203, Gaoli Auto Expo City, Huishan, Jiangsu, China.

A5-203, Gaoli Auto Expo City, Huishan, Jiangsu, China. Annie +86-189 61880758 Tina +86-15370220458

GOODFORE Electric weaving machines and Textile Machinery allow us to produce fabrics far more quickly compared to manually weaving fabrics. In ancient times, textiles were made by manually weaving threads together with basic implements. That was a long and tedious process. However, thanks to electric weaving machines, we can produce fabric faster and more efficiently. They are so special because these machines can make so many different patterns, colours and designs. They are basically a super sidekick in the textile world.

To begin with, these machines operate considerably faster than hand weavers. This speed allows businesses to manufacture many more textiles in less time. Just think of being able to create lots of shirts, dresses or blankets simultaneously. Second, electric machines as well as Weaving Loom are programmable to produce elaborate patterns and colors. This is especially crucial since this indicates that businesses are able to tailor the fabrics to fit customer demand. If someone wants a blue piece of fabric with stars, the machine can get that done easily. Finally, electric machines can run with a smaller crew, which enables businesses to make more textiles with fewer people. This can help conserve funds and resources.

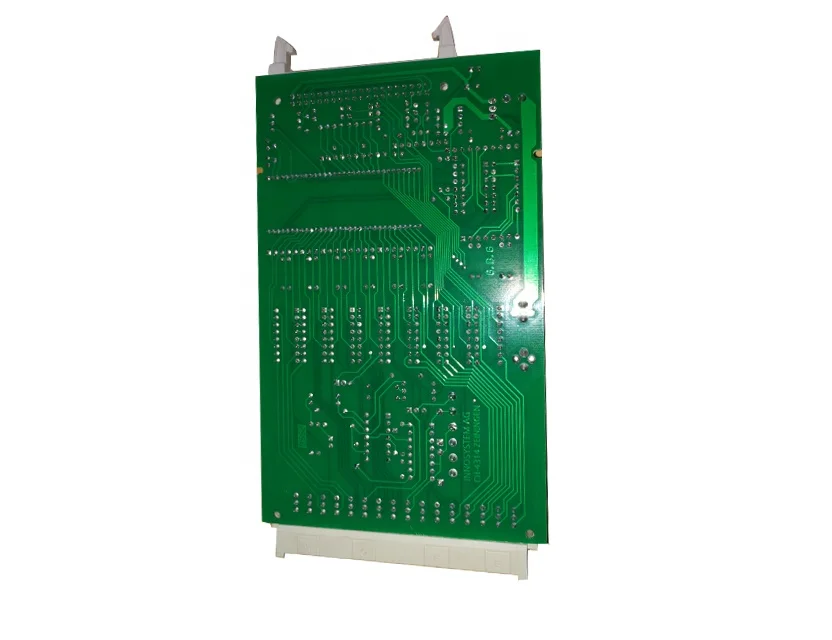

Electric weaving machines along with Cloth Label Cutting and Folding Machine use electricity to perform this intricate task, and are therefore very-special, complex machines. They are fast and efficient by design. Within these machines are numerous components such as gears, motors, and other tools that work together in consultation. The machines work in concert, producing fabric far faster than anyone can by hand. So, the next time you see a gorgeous piece of fabric, you can bet these nifty machines had a hand in it.

GOODFORE Electric weaving machines as well as Needle Loom Machine are leading to many exciting innovations in textile manufacturing. For one, they greatly streamline how textiles are made. It means that companies can produce a high-volume of textiles in a shorter time, which is very good for the demand of the customers. Second, these machines are also creating custom textiles for businesses. Using electric machines, they are able to create a wide range of styles, patterns and colors. That versatility allows them to produce precisely what consumers want to buy. Finally, electric machines are showcasing a greener side of the textile industry. The industry can push towards sustainability if they use less hands to work or generate smaller quantities of waste.

And it does not stop there: Electric weaving machines are opening up new ideas on creating fabrics in a new era. These machines help companies develop fabrics with designs and patterns that are more intricate than ever. In hindsight, this allows more room for creativity and opens the opportunity to create a wider range of unconventional fabrics. It also becomes easier to customize textiles with these machines so customers get what they want, hassle-free.

Copyright © Goodfore Tex Machinery Co., Ltd. All Rights Reserved - Privacy Policy - Blog