A5-203, Gaoli Auto Expo City, Huishan, Jiangsu, China.

A5-203, Gaoli Auto Expo City, Huishan, Jiangsu, China. Annie +86-189 61880758 Tina +86-15370220458

Hello! We’re going to explain today about textile manufacturing machines. Have you thought about where your clothes come from? GOODFORE Textile Machinery is really essential for producing clothes and other fabric stuff we use day. All of the shirts, pants, or dresses that we wear, would not have existed without these machines. So, let’s explore how these machines help us further into the world of textiles.

The textiles manufacturing world has seen many exciting changes over the years. A huge part of that has been using computers to aid in the design and creation of fabrics. These computer programs, which are known as computer-aided design (CAD), enable factories to replicate their designs on a screen before even beginning to produce anything. It allows them to see how the fabric will work and to make adjustments if necessary. When they are prepared, they can also turn to computer-aided manufacturing (CAM) to assist in making the fabric. That makes the machines much faster and more accurate. These are such advanced tools that there can be a faster and more accurate production of clothes than before.

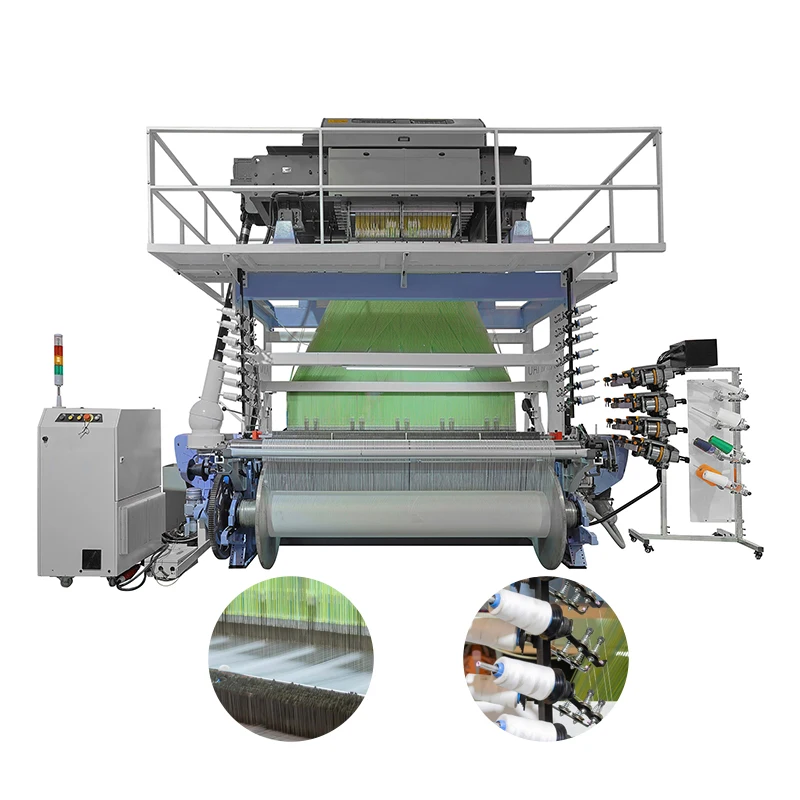

With the help of new technology, the textile and apparel industry is definitely turning around for better and is doing wonders. Examples of the coolest new tools are 3D printing, laser cutting and nanotechnology. The 3D printing techniques have made it possible to manufacture unique and detailed fabrics which might be too difficult to produce with other: more industrialized methods. It makes it possible for designers to create unique and sophisticated designs. Another significant tool used in fabric industries is GOODFORE Weaving Loom, it makes precise cuts, no over pockets which make edges great. Nanotechnology involves working with materials at an extremely small scale that can help to make textiles much stronger and resilient. This allows the fabrics of your clothes to last longer and perform better.

Because of modern textile machines factories can create much more of the product in a limited time. GOODFORE Textile Machinery Parts that are used to create fabrics can work at extremely high speeds and, as a result, can produce a ton of fabric in a very short amount of time. Other machines cut and sew automatically, meaning that they can do these tasks without requiring hand operations. This is great because this counts factories to produce more items in a shorter time and save money in labor costs. And with those machines, factories are able to meet the high demand for clothing and fabrics people need.

The use of automatic machines is also another prominent trend in the textile industry. These machines are very useful because they are fast and precise which ensures a good quality of products. Some machines specialize in perfect color matching because they want different fabrics to look good together. Some are intended to locate and mend issues in the fabric, like holes or uneven stitching. They allow the machines to produce higher-quality products, essentially ensuring that the clothes we wear are not only gorgeous, but also durable, all while requiring less maintenance of the workers.

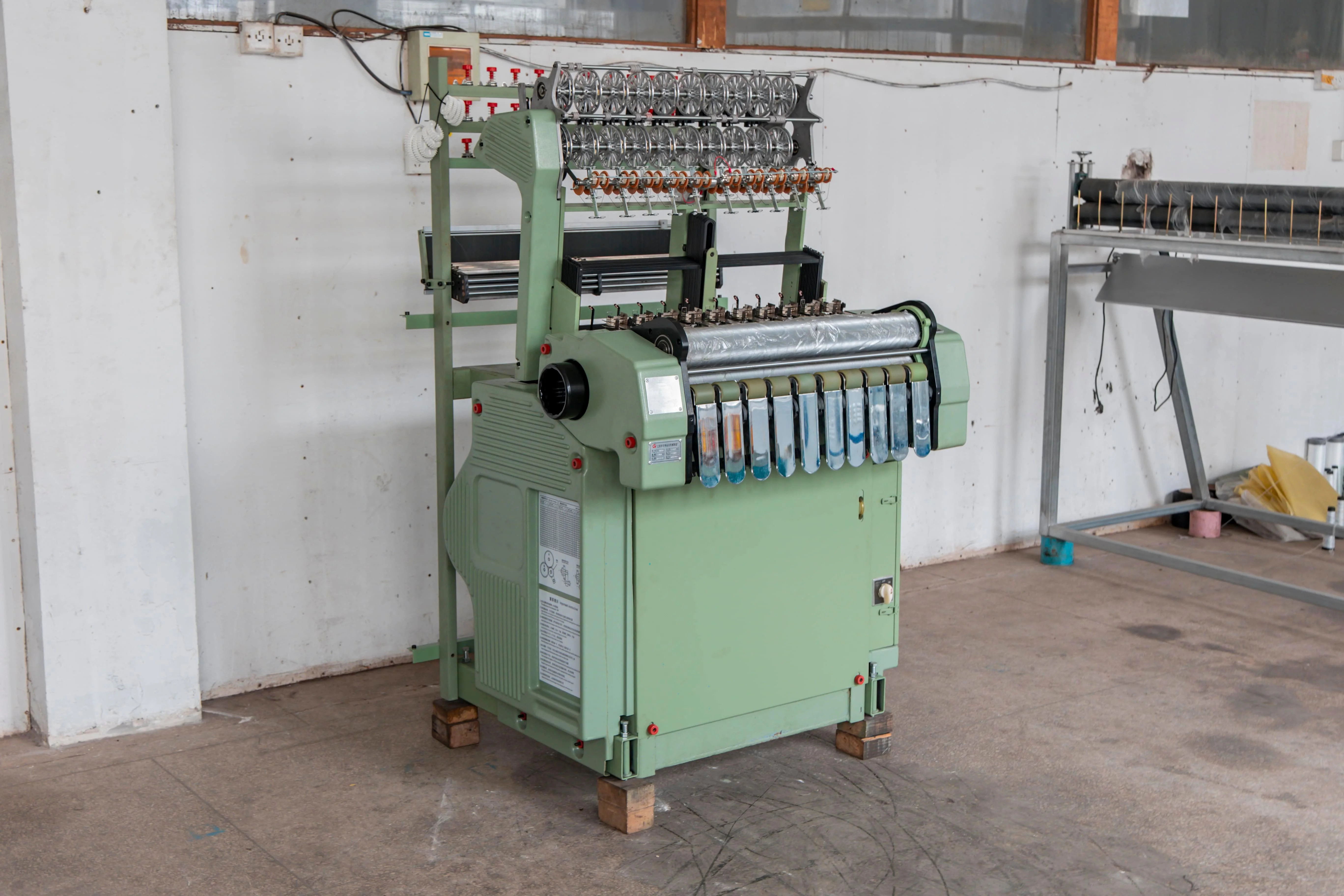

Designing and working with the machines is also a very big part of the textile industry. There is always some shuffle for pulling out much efficient and eco-friendly machinery. Other pumps nowadays are manufactured with advanced water-cooled motors that use much less energy, but still get the job done efficiently. GOODFORE Needle Loom Machine also have sensors that detect when the machine needs repair or maintenance. That means the machines can keep working more effectively for longer without breaking down. These changes benefit us all since they help save our planet while allow the machines to last longer.

Copyright © Goodfore Tex Machinery Co., Ltd. All Rights Reserved - Privacy Policy - Blog