A5-203, Gaoli Auto Expo City, Huishan, Jiangsu, China.

A5-203, Gaoli Auto Expo City, Huishan, Jiangsu, China. Annie +86-189 61880758 Tina +86-15370220458

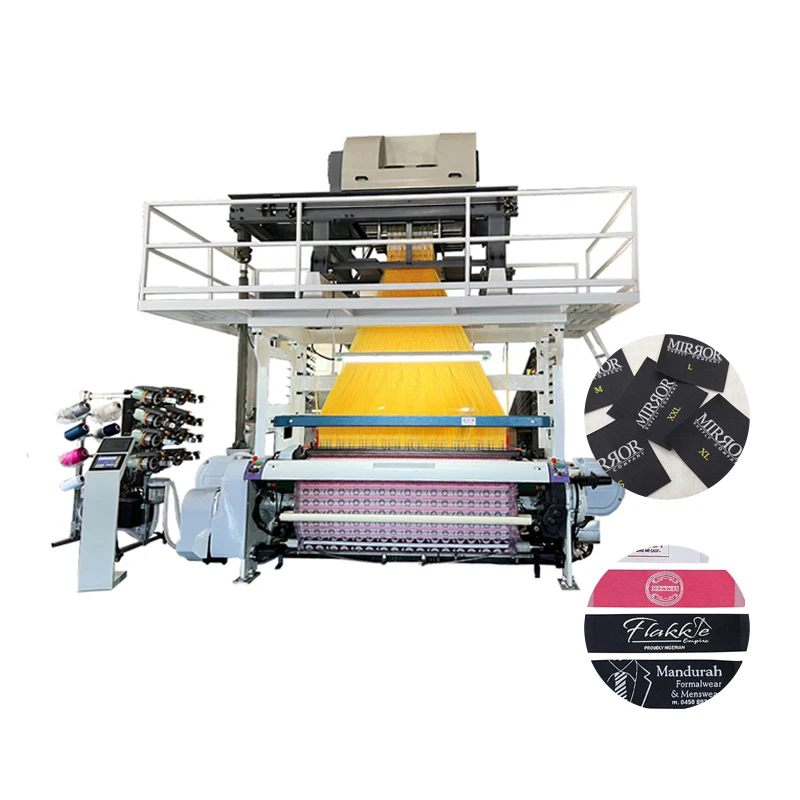

A textile mill machine was invented long before mine, in the late 1700's. It was a critical period for producing cloth. Prior to the invention of this machine, humans fabricated cloth manually using a kind of device called a handloom. 1 year ago Making cloth by hand took ages; it was manual labor in the highest degree. We used to have to think with our hands and arms, and it would take all day long to weave a piece of cloth just as big as a piece of paper. But then, it all changed with the GOODFORE Textile Machinery. This made crafting cloth a much quicker and simpler process for all. The earliest of these was called the spinning frame. This machine used water to assist in the process of turning cotton into yarn — the thread used to create fabric.

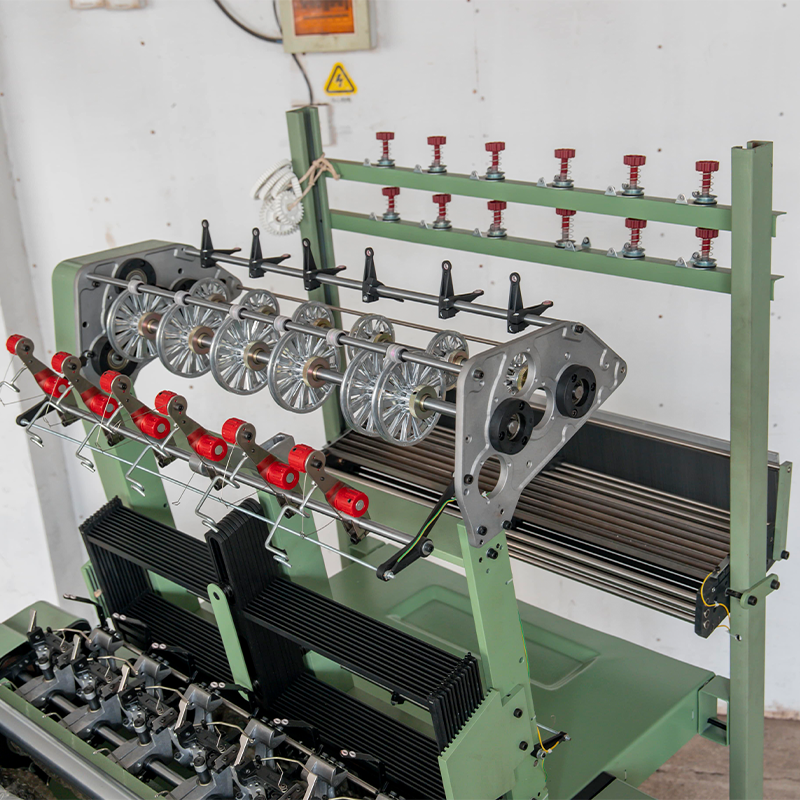

There are many GOODFORE Textile Machinery Parts of the textile mill machine which work all together to produce fabrics. Important parts are the spinneret, take-up roll and winder. The spinneret is a little device that makes thread by forcing fibers out of small holes. This is the way the thread is made. A take-up roll then winds the thread into a spool. The spool is almost a small cylinder like the one that the thread is wrapped around. Finally, the winder turns the spool to prepare it for use in producing fabric.

Handloom was being used to make all cloth before the invention of powerloom and Needle Loom Machine. Weavers sat at the handloom, day in and day out, fabric came through their hands and their feet. Making cloth this way was incredibly slow, and took hard work and skill. But the story changed with the powerloom. It was a new kind of machine that operated by steam, water or electricity. This was far quicker than a handloom.

The textile mill machine as well as GOODFORE Weaving Loom operates by spinning, weaving, and finishing fabrics. First, they clean and prepare the raw materials, such as cotton, wool or silk, to use. Specifically, separating the fibers, cleaning them and preparing them for spinning. The fibers are then spun into yarn and wound on coils. That yarn is the fabric to be made from it. The woven fabric is created using the powerloom once the yarn is prepared. This is where the magic comes to be.

The machine of textile mill is essential for the fast and simple fabrication of fabric. Today, textile mills worldwide continue to use this machine to produce a wide variety of fabrics, including those from cotton and silk. Without the machine they created for the mill, you would need a significantly longer time and a much more difficult to produce fabric. It transformed the way we produce textiles and how we are able to have much more options of fabrics to choose from.

Copyright © Goodfore Tex Machinery Co., Ltd. All Rights Reserved - Privacy Policy - Blog