Sustainable Process in Label Making Production

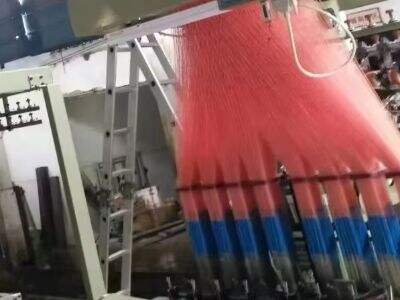

When we are label making, the only way to waste less and get more is streamlining production for shuttle loom weaving. It easier said than done, but we have to reimagine how we produce labels and redesign the label production process – and do all of this more quickly. We cut flow of waste and save money & time by streamlining production processes.

Use of Biodegradable Materials in Label Production

We can also make our label better by starting to use cloth loom the materials that are eco-friendly. As eco-friendlier materials that can be recycled or repurposed. It also helps a whole lot in reducing waste we produce and helping Earth prosper.

Improving Operational Efficiency with Digital Label Printing Technologies

The use of digital label printing technologies can make label making more efficient for operations. Digital printing enables quick and accurate label printing with less waste. It saves us time and resources, like gasoline or electricity and in some cases, water, to clean the mess. GOODFORE uses modern, digital printing methods to ensure the highest quality labels at more competitive prices.

Reducing Waste with Inventory Streamlining

Tag Making Waste Reduction by Inventory Management Keeping track of our inventory cloth weaving loomand only ordering based upon what we need helps to reduce waste in addition to saving us money. By keeping track of inventory, we can help ensure that the parts are on hand when we need them to keep our label manufacturing process running smoothly.