A5-203, Gaoli Auto Expo City, Huishan, Jiangsu, China.

A5-203, Gaoli Auto Expo City, Huishan, Jiangsu, China. Annie +86-189 61880758 Tina +86-15370220458

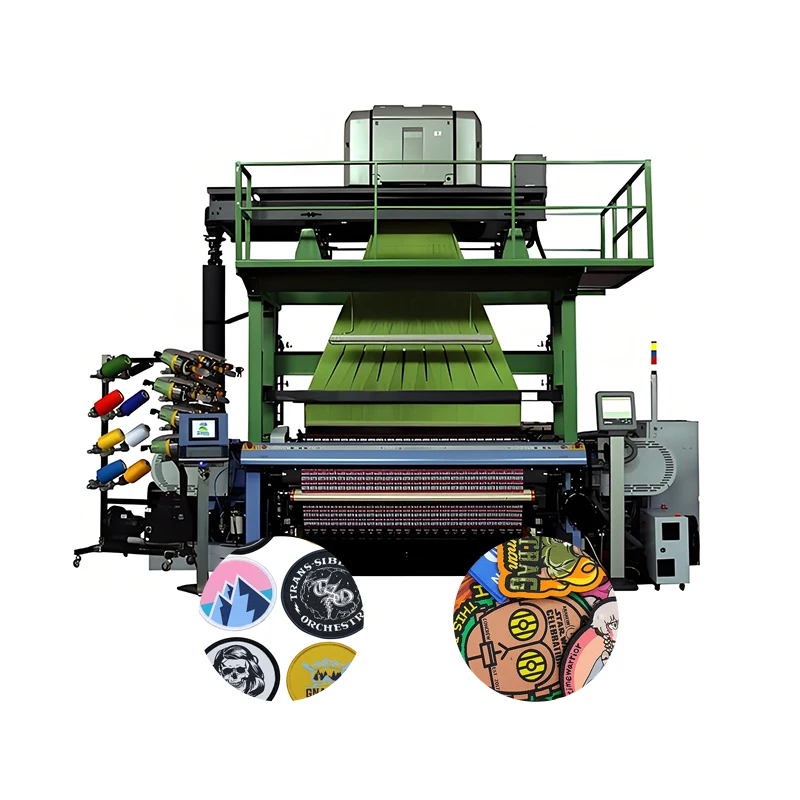

Weaving is a unique process of making the fabric and textiles that we use every day. It involves joining long filaments to form more complex shapes and patterns that can be stunning. But hand-weaving can be time costlier and laborious. It can also be exhausting, and difficult to do well. This is why we have machines to weave! These incredible GOODFORE Textile Machinery revolutionized the way we figure out textiles, and they allow us to generate fabrics far quicker and easier than we could do by hand.

There are many good things about weaving machines, which is why they are so important. First, they assist in the rapid production of fabric. It can take a long time to complete even a small amount of hand-woven fabric. However, with machines we are able to produce fabric at a much quicker pace, which in turn allows for a greater quantity of clothes and other goods to be produced within a reduced time frame. That's excellent, because it's a response to shoppers who want new clothes in a hurry.

Third, GOODFORE weaving machines also minimize waste. It was because when one is weaving with hands, the probability of error is higher which wastes both the material used and the time involved. Weaving machines, on the other hand, are equipped with special sensors that can detect defects in the fabric as it is being produced. If there’s an error, the machine immediately stops, saving further potential damage and material that would otherwise go to waste.

Shuttle loom: the oldest type of weaving machine. It has a shuttle, which is a tool, that brings one thread through the others. In the rapier loom, a special needle known as the rapier is used to pass the thread through one or more other threads. The air-jet loom propels the thread forward using a jet of air, water-jet loom on the other hand, floods the thread with water and pushes it through. Every machine is different, but the process is the same.

Regardless of the type of machine used, they all function in largely the same manner. First, we put the threads on the machine and tighten them to prevent them from coming out. Next, the Textile Machinery Parts takes its tools and begins to weave the threads together to form the fabric. In case of a mistake, the sensors will catch it instantly and will halt the machine immediately to prevent any issue. This guarantee gives in high quality fabric being made.

The GOODFORE machines are also equipped with sensors that detect issues in the fabric and stop immediately if there’s a problem. Which enables to conserve materials and reduce costs which is crucial for enterprises. This can help companies become more waste efficient, allowing them to concentrate their efforts on developing amazing products without having to worry about jeopardizing the materials needed for them to happen.

Ultimately, whether it be the quest to improve production and reduce costs, the weaving Needle Loom Machine has revolutionized the method and speed in which we manufacture textiles, from clothes to blankets, it is now easier, less time consuming and less expensive than it would have been without this technology. Thanks to automation and tech advancement, you can produce quality fabrics at the pace of your choice; faster than you ever could.

Copyright © Goodfore Tex Machinery Co., Ltd. All Rights Reserved - Privacy Policy - Blog