A5-203, Gaoli Auto Expo Urbs, Huishan, Jiangsu, Sinarum.

A5-203, Gaoli Auto Expo Urbs, Huishan, Jiangsu, Sinarum.Annie +86-189 61880758 Tina +86-15370220458

Villus est materia mollior, fluffier et calefacta, quam homines utuntur ad conficienda vestimenta, stragula et alia instrumenta calefacientia. Vestes ex villis manu factae sunt per milia annorum. Ibi illi accipiebant villam, torquendo eam manibus suis et texendo in pannum. Sed nunc tempora mutantur et habemus machinas speciales quae accelerant et levant onus. GOODFORE: Unus ex fabricatoribus horum mirabilium Textilis Machinamenta . Exploraremus quomodo ipsae adjuvant ad texendam villam et cur tam necessariae sint.

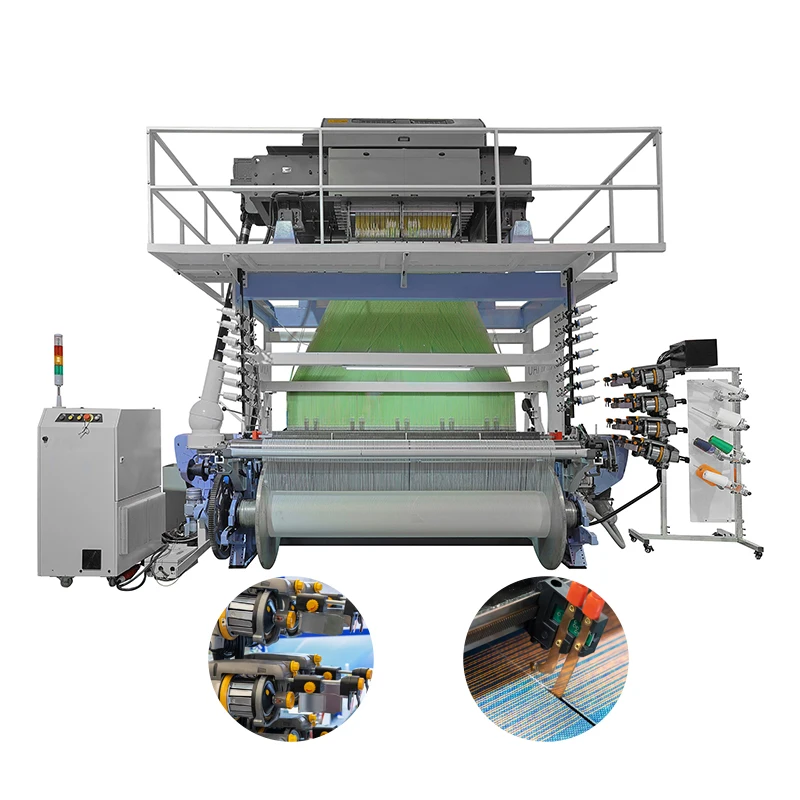

Machinae textiles villae adiuvabunt producere producta villorea citius et efficientius. His machinis utendo, villa potest ire a lana ad pannum intra horas, contra dies vel septimanas prius. Machinae multam partem laboris gravis faciunt: constringendo villam in filum, Tela Loom texendo eam in pannum et deinde secando eam in partes quae possunt fieri ad conficienda singula producta. Hoc significat quod fabrique plus producta villorea producunt in breviore tempore, et hoc sensu faciunt plus pecuniae et opera sua fluenter gerunt.

Etsi machinae texiturae lanae modernae videantur, conceptus utuntur qui iam diu existebant. Haec simili modo operantur quam homines texebant lanas olim (manu). Unicum instrumentum utuntur, quod Partes Textilis Machinamentorum nominatur navicula, quae filum transportat in structura quae dicitur telares. Hoc fuit methodus communis texturae panni lanei per saecula! Differentia est quod machinae possunt texere pannum celerius quam ullus homo manu facere potest. Haec velocitas multum prodest, praesertim cum crescit demandatio productorum laneorum hodie.

Nec mirum quod textura lanae machinae solutio efficax sunt et faciunt processum productionis velocior et sinunt fabricas ut producant maius numerum productorum lanae altius qualitatis. Haec machina secundum ordinem nimis fixum operantur, uniformitatem inter partes pannorum servantes, ita ut omnes informationes eandem magnitudinem et crassitudinem habeant. Hoc refert quia clientes amant vestimenta bene facta et quae habent aliquam formam. Haec machina etiam possunt producere designia atque formas attractivas et nimis detailed in panno lanae. Quidam horum designiorum possunt esse difficiles manu facere, sed machina hoc multo facilius reddit. Ita, fabricae possunt producere plura producta lanae frigida quae captant attentionem plurium consumerium et eos iuvant vendendo plura producta.

Machina texendi lanae potest literaliter transformare productionem lanae in texilem. Huiusmodi machinae multa praebent utilia, ut celeritas, productio altioris qualitatis et praecisio maxima. Haec machinae sunt una ex magnis commoditatibus, quoniam etiam possunt operari 24/7 sine necessitate requiei. Hoc significat quod productio potest esse multo citius et fabbricae possunt convenire cum desiderio suorum clientium. Coniungendo plures ordinationes, machinae possunt texere maiorem massam pannorum lanae simul, quod societatibus permitit accommodare ordinationes celerius. Praeterea, machinae servant omnes productos lanae eadem mensura et crassitudine. Maximum praesidium venit ex hoc facto, quod, contra methodum classicam texendi lanae, hoc tempus magnum salvabit et eandem constantiam semper praebet.

Machinae textiles GOODFORE accelerenter innovantur, industria lanifera expanditur et requisita societatis hodiernae implent. Adhiberi possunt ad faciendum tela lanaea nova et inventiva pro varietate productuum. Item tela carpeta lanaea composita ex designis minutis et intricatis, quae magis demandantur a emptoribus, conficere possunt. His machinis, fabrique textilia clientibus varietatem productuum elegantium lanarum praebere possunt. Hoc ambitum habere eos iuvat plures clientes attrahere et in negotiatione prosperari. Industria lanifera hoc progressu proderi potest, cum technologiae recentes in textura et productione textilium evoluantur, formas novas penetrantes ut necessitates fabricatorum et consumitorum impleant.

Copyright © Goodfore Tex Machinery Co., Ltd. Omnia Jura Servata - Politia Privati-Blog